As NASA plans its space missions, efforts are underway to identify technologies that must improve to make such trips feasible. Through this effort, valves and flow management systems have seen vast improvements in reliability, cost, speed, and simplicity of design. The following technologies are ready for licensing in a range of industrial applications.

A Versatile, Durable, Low Maintenance, Fast-Acting Relief Valve

Developed for low-pressure testing of a vacuum chamber in the Kennedy Cryogenics Laboratory, the Magnetic Pressure Valve opens at precise cracking pressures. Using a magnetically-controlled relief valve instead of a spring-based one enables quick-open on/off relief operation when overpressure is reached. Its magnetic field rapidly decays as the fluid medium pushes the valve poppet to an open position. In contrast, a spring-based relief valve requires increasing pressure and force to compress the spring and open the relief valve continually. The magnetic relief valve reduces these design complexities by eliminating the spring.

The relief valve mechanism is fully sealed and isolated from the flow path of the fluid/gas media. This may lead to lower maintenance than is currently required for pressure relief valves because relief valve springs are exposed to corrosive environmental factors and system fluids. The magnetic pressure valve can handle more significant flow rates and a more extensive range of pressure values. Possible applications for this new technology include pressure vessels, vacuum chambers, low-pressure systems, basic industrial systems, and gas and liquid systems.

A Simple, Compact, Low-Cost, Modular Assembly for Simplified Hi-Res Flow Visualization

A Simple, Compact, Low-Cost, Modular Assembly for Simplified Hi-Res Flow Visualization

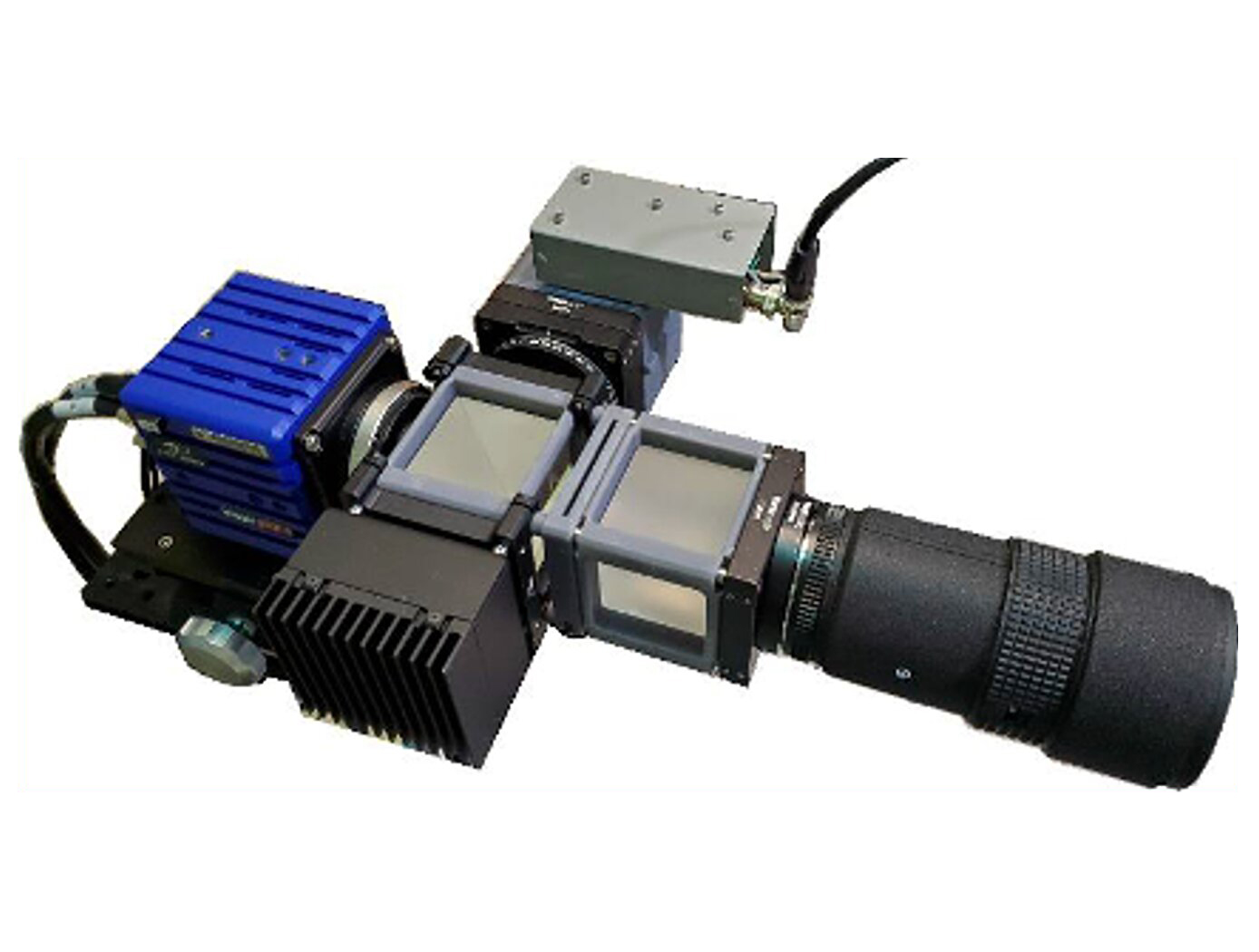

NASA’s Langley Research Center has developed a simple, compact, easy-to-use imaging system to enable hi-res flow visualization. The assembly can be mounted in front of a camera to allow focusing schlieren imaging capability. The design drastically reduces the complexity and time required to align a focusing schlieren imaging experiment.

Conventional focusing schlieren imaging systems and projection-based analogs require burdensome grid alignment and peripheral resources (e.g. separate source and cutoff grids, projectors, specialized software). NASA’s method leverages a single physical grid as both the source and the cutoff grid, so the system is self-aligned and does not require specialized software.

This new technology also costs less than other projection-based alternatives. The assembly is vibration insensitive as the self-aligning nature of the instrument prevents grid misalignment issues common to currently employed focusing schlieren alternatives. It is also high-speed imaging capable, demonstrating framing rates up to 1 MHZ depending on the camera and light source used. The system’s components can be optimized for environment, experiment, and cost. It can also employ a variety of light sources, cameras, polarizing prisms, and retroreflective materials. Potential applications for the system include aerospace, thermal management, medical contamination control or diagnostic imaging, manufacturing, ventilation, and education.

A Scalable, Low-Cost Poppet Reduces Valve Leakage by Three Orders of Magnitude

NASA researchers have designed a Self-Aligning Poppet that enables low leakage for valves using seat alignment technology. This new technology eliminates the need to precisely control interfaces between poppet sealing surfaces and valve seat seals. The self-aligning function ensures that the poppet is always centered, parallel to the seat, and perpendicular to the actuator action line. This substantially reduces the energy required to make a tight seal. Reduced size, weight, and power requirements relative to traditional valves are all benefits of the technology, significantly reducing cost.

Testing has shown that NASA’s self-aligning poppet reduces leakage in aerospace cryogenic valves by three orders of magnitude. The technology is scalable, previously incorporated into valves with 1 to 8 line sizes, but capable of scaling down to line sizes under 1. Full-scale prototypes have been tested in cryogenic systems, subjected to thousands of cycles, and remain fully operational.

This technology may find use in industries requiring sealing to prevent critical or hazardous chemicals from leaking into the environment and low-leak or long-duration storage of expensive or limited resource commodities. Examples of applications include cryogenic valves, petrochemical valves, and plug-type valves.

A Leak-Free, Low Maintenance, Low Downtime Floating Piston Valves

A Leak-Free, Low Maintenance, Low Downtime Floating Piston Valves

NASA’s Floating Piston Valve consists of a solid piston floating in a medium to control the flow stream. It is designed to be axially and radially balanced within the flow stream whether the valve is in the open or closed position. The only force imparted onto the piston is that which the operator chooses to input onto it. This design allows for consistent seating force regardless of the pressure drop across the valve.

This technology also can eliminate the valve and stem seals, a conventional actuator, valve actuator adjustments, and most flow-induced thrust forces. The valve consists of five parts, with a few simple seals incorporated into a well-protected design. The simple design allows for use in nominal or extremely high pressures and soft or hard metal seats. The invention also reduces downtime and maintenance costs while increasing valve reliability and seat life. The floating piston valve is hermetically sealed and leak-free, with no fugitive emissions. It could see use in power plants, petrochemical plants, chemical industry, refineries, pressurized storage tanks, cryogenic fluid systems, pharmaceutical manufacturing industry, and fast actuation applications.

To browse NASA’s entire portfolio, please click here.

Follow us on LinkedIn, Twitter, and Facebook to stay up-to-date on all our latest technology offerings.