The Federal Labs Consortium (FLC)’s Federal Lab Education Accelerator (FLEX) program fosters collaboration between federal labs and academic institutions. The program facilitates market assessments that are essential for the commercialization of new technologies. FLEX works with students in MBA programs, connecting them with the technology portfolios of federally funded research and development centers.

The Federal Labs Consortium (FLC)’s Federal Lab Education Accelerator (FLEX) program fosters collaboration between federal labs and academic institutions. The program facilitates market assessments that are essential for the commercialization of new technologies. FLEX works with students in MBA programs, connecting them with the technology portfolios of federally funded research and development centers.

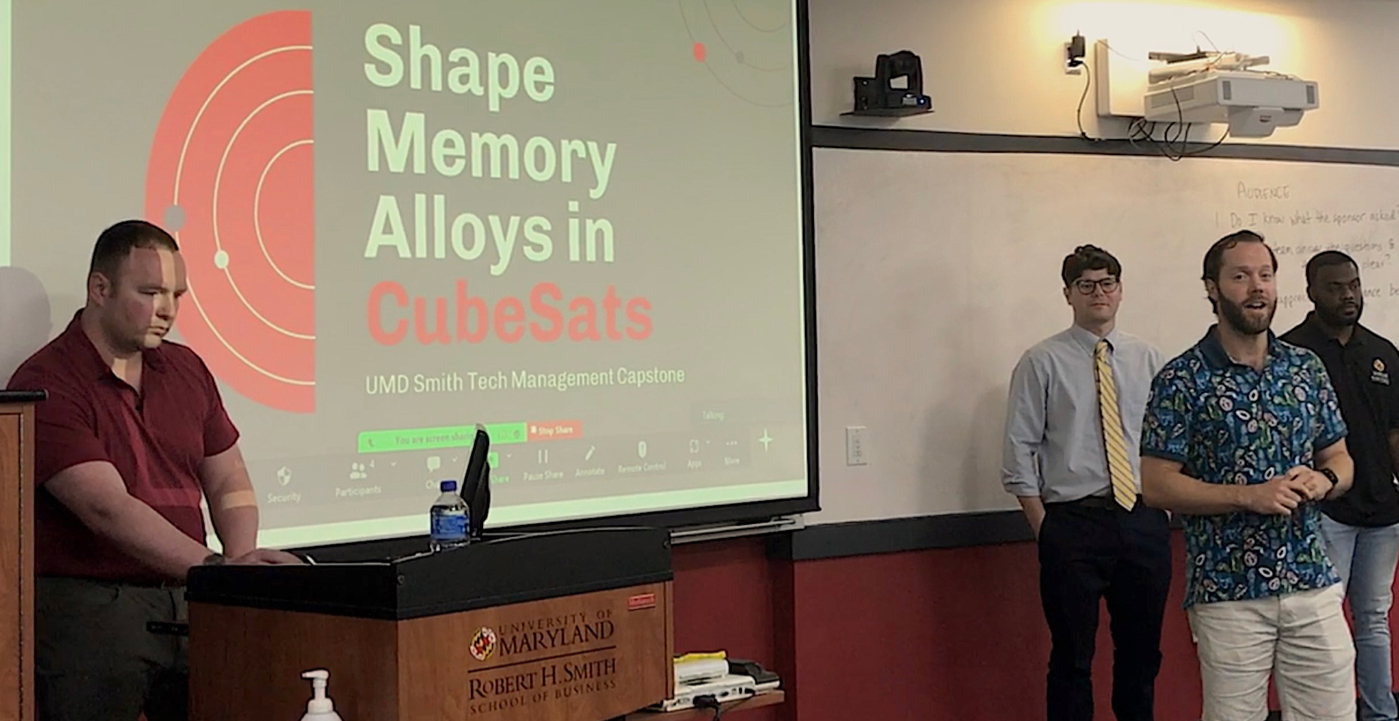

The University of Maryland (UMD) Robert H. Smith School of Business Technology Management Graduate Program Capstone students worked with NASA’s Glenn Research Center Technology Transfer Expansion (T2X) team through the FLC FLEX Program to support a technology commercialization project.

A technology developed by innovators at Glenn Research Center became the focus of the FLEX MBA Action Learning Project Capstone, providing a unique opportunity for graduate students at UMD to flex their skills in technology management, development, and market assessment.

They explored use cases and commercialization for Glenn’s shape memory alloy (SMA) mechanism for CubeSats. Their research supported the use of this emerging technology to address the growing problem of space junk.

“We designed Maryland Smith’s tech management program to prepare America’s next generation of technology strategists to innovate responsibly across both business and government,” said Frank Goertner, Director of UMD’s Graduate Program in Technology Management and the team’s faculty facilitator. “There’s really nothing more exciting than to see that happen before they even graduate – above all for a partner like NASA on an issue of such lasting global importance.”

The students conducted market research and interviewed diverse stakeholders in the CubeSat industry, and this group also had the unique opportunity to speak with the technology inventor Dr. Othmane Benafan, who provided additional insight on the features and benefits of the technology.

The Capstone team learned that the use of burn-wire actuators frequently leads to mission failure, while shape memory alloy (SMA) actuators are a more reliable mechanism for successful CubeSat deployment. Their research quantified the elevating cost risks from deployment failures and the space junk they can generate.

The students’ research concluded that a U.S. policy directive was the best way to move both the government and commercial markets rapidly toward new standards to reduce space junk. As these forward-thinking students predicted, the Federal Aviation Administration (FAA) has since proposed a rule to limit the growth of new orbital debris in Sept. 2023. The UMD team also conducted a financial analysis of the target market for NASA’s new junk-reducing technology and demonstrated a significant cost-based business reasoning for market adoption of SMAs instead of burn wire actuators.

The project deliverable included a final brief of the team’s research and recommendations for strategy and marketing for the NASA Glenn Technology Transfer team with a supporting document package provided for further review.

The project deliverable included a final brief of the team’s research and recommendations for strategy and marketing for the NASA Glenn Technology Transfer team with a supporting document package provided for further review.

“I appreciated the opportunity to work with the UMD students and learn more about the CubeSat industry growth trends and cost savings comparison data put together by their team”, said Jeanne King, Innovative Partnership Specialist at NASA Glenn. “This is a great approach for taking a deep dive into a technology’s commercialization”.

Visit Technology Transfer University to learn more about the Technology Transfer University (T2U) program, and how it connects students with federal government research and technology for their classrooms.