Advanced Solid-State Metal Additive and Extrusion Technology Webinar

When: Tue, 11/19/2024 - 2:00 PM (Eastern Time)

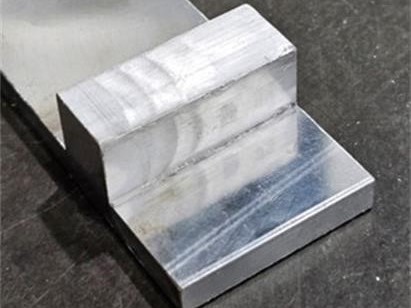

Join us for an exclusive webinar to explore NASA Marshall Space Flight Center's groundbreaking Novel Advanced Solid-State Additive (NASSA). These processes include Conventional Friction Stir Deposition (C-FSD), Bobbin Friction Stir Deposition (B-FSD), and Conventional Friction Stir Extrusion (C-FSE). These three processes leverage an innovative end-effector approach to revolutionize metal deposition and extrusion by offering modular, customizable capabilities. Cost-effective and flexible, the NASSA processes can work with any metal alloy that is amenable to Friction Stir Welding (FSW) processes, including aluminum alloys and other lightweight or exotic alloys. During this webinar, learn how this state-of-the-art technology could transform manufacturing processes and explore opportunities for licensing and commercialization.

For more information on these technologies, please visit:

Conventional Friction Stir Extrusion Machine (MFS-TOPS-126)

Friction Stir Deposition Innovations (MFS-TOPS-127)

Dr. Josef Cobb is a Weld/Mechanical Engineer for NASA. Specializing solid-state joining and additive processes, he has led qualification and risk reduction efforts for Friction Stir Welding (FSW) processes on NASA’s Space Launch System (SLS) and other flight projects, ensuring the highest standards in NASA’s manufacturing capabilities. He is currently running several joint R&D projects with NASA and other commercial vendors regarding FSW and friction stir deposition (FSD) processes. He is also involved in alloy development projects for both FSD processes and high entropy alloys for 3D printing. He holds a Ph.D. in Mechanical Engineering from Mississippi State University and a licensed Professional Engineer in the state of Alabama.

Zach Courtright has been serving as the In-Space Manufacturing Portfolio Manager at NASA for the past year. Previously, he worked for eight years as a Welding Engineer at NASA’s Marshall Space Flight Center. During his time at NASA, he has performed technical and project management responsibilities by proposing, supporting, and leading an array of research and development projects involving welding, additive manufacturing, electronics, nondestructive evaluation, and recycling. Recently, he has participated in and led projects pertaining to the development of in-space laser welding and on-demand manufacturing of electronics. Other research efforts that he is focused on are solid-state additive manufacturing and high-throughput mechanical testing, both of which have terrestrial and in-space manufacturing applications (two patents pending). He holds a bachelors and masters degree in Welding Engineering and is currently in part-time pursuit of a PhD in Materials Science and Engineering.