Infrared Thermography for Additive Manufacturing Webinar

When: Tue, 6/3/2025 at 2:00 PM (Eastern Time)

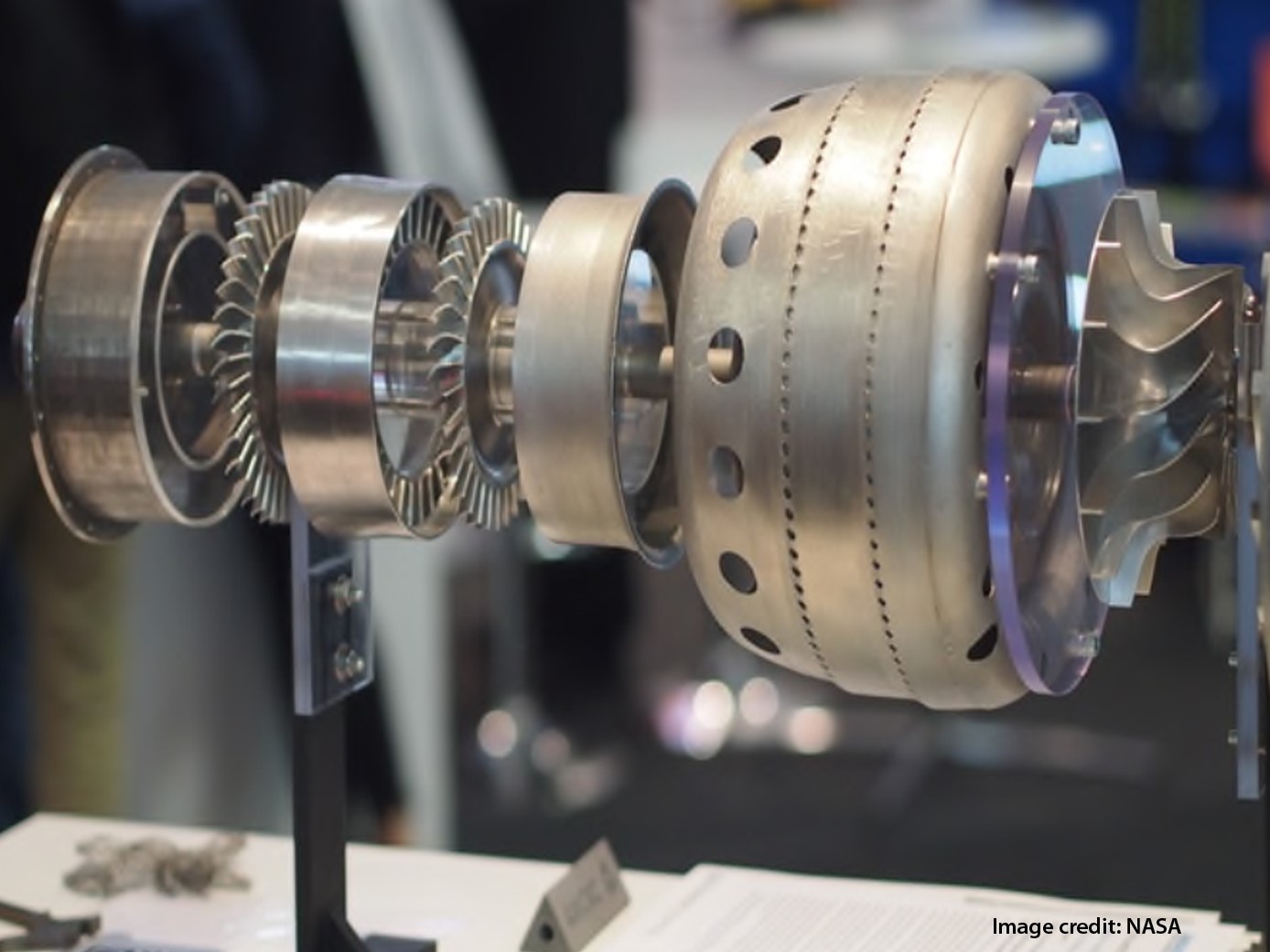

In additive manufacturing (or 3D printing), ensuring the integrity of each layer is critical for high-quality production. NASA's Langley Research Center has developed a non-destructive evaluation method based on transient infrared thermography, which provides a detailed, real-time analysis of additive manufacturing deposits. This innovative technology allows for precise detection of flaws such as voids, cracks, and disbonds as the structure is built layer by layer.

Learn how this infrared thermography system enables researchers and manufacturers to assess material properties, inspect the melt pool and evaluate deposition quality with superior definition. The results can be archived with the final product, creating a complete record of structural integrity.

For more information on this technology, please visit:

https://technology.nasa.gov/patent/LAR-TOPS-265

Mr. Joseph Nomasa Zalameda graduated from Old Dominion University in December, 1986 with a BS in Electrical Engineering and received his Masters degree from the College of William and Mary in Applied Science in August 1996. His areas of research are in thermal nondestructive evaluation (NDE) and sensors development and characterization for NDE. He started his civil service career from 1987-2009 as an Army Research Laboratory researcher at NASA Langley. He led the NDE effort for wide area inspection of composite rotorcraft structures under the Survivable Affordable Reparable Airframe Program (SARAP). He served from 2002 to 2009 on the technical cooperation panel (TTCP) international committee for NDE for Asset Life Extension as the US Army representative and was presented a scientific achievement award at the Pentagon, Washington DC in 2010.

From 2009 to present, as a NASA employee, he has worked on several projects including leading the mission radiometric calibration efforts for the Hypersonic Thermodynamic Infrared Measurements (HYTHIRM) for numerous shuttle missions and as task lead within NASA’s Advanced Composite Project developing in-situ inspection methods for composite load testing. He served as conference co-chair and chair for the 2015 and 2016 SPIE Thermosense conferences respectively and again as conference co-chair and conference chair for the 2020 and 2021 SPIE Thermosense conferences. His most recent research efforts have been in in-situ NDE for metals additive manufacturing. He has received the NASA Exceptional Technology Achievement medal for 2019. He holds 7 patents and has published over 80 research papers.