NASA's Additive Manufacturing Alloys for High Temperature Applications Webinar

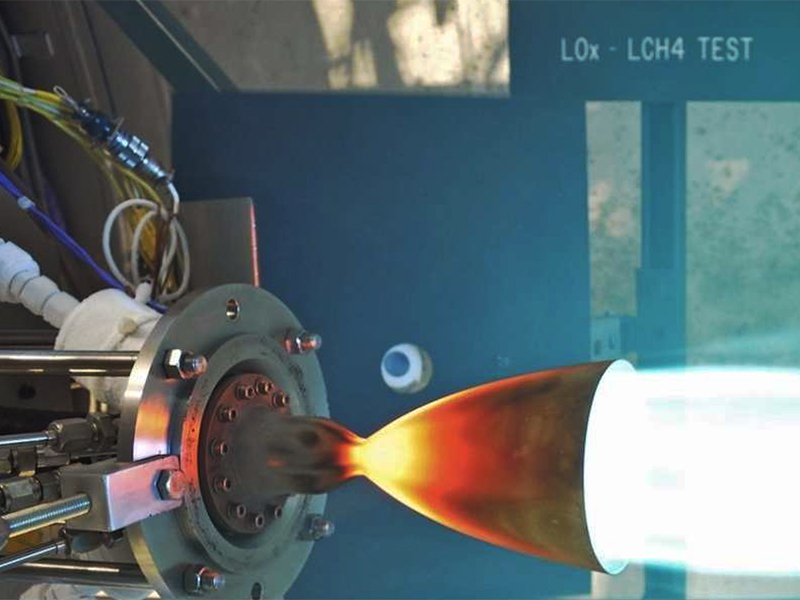

Innovators at the NASA Glenn Research Center have developed a new oxide dispersion strengthened medium entropy alloy (ODS-MEA) using additive manufacturing (AM). ODS alloys, in which nano-scale ceramic particles are distributed within the metal, were originally developed to enhance mechanical properties (e.g., creep resistance, tensile strength, microstructure integrity) at extreme temperatures. Thus, such alloys show promise for metal components of gas turbines, rocket engines, nuclear reactors, and other high-temperature applications. However, the conventional mechanical alloying process is highly inefficient, time-consuming, and costly to produce such alloys. By contrast, NASA's ODS-MEA is designed for production via selective laser melting. The alloy can be fabricated into complex geometries and is resistant to stress cracking and dendritic segregation. When exposed to extreme temperatures, it is not susceptible to deleterious phase changes and requires limited post-processing.

For more information about this technology, please click here.

During the webinar, you will learn much more about this novel technology and how NASA's technologies and capabilities are available to industry and other organizations through the NASA Technology Transfer Program.

Dr. Timothy Smith Graduated from Wright State University with a Bachelors Degree in Mechanical Engineering in 2011. In 2016, he Graduated from Ohio State University with a PhD in Materials Science. He began career at the NASA Glenn Research center through the Pathways Internship Program in 2015. Dr. Smith currently works at NASA’s Glenn Research Center where his research focuses on the production, microstructural characterization, and deformation analysis of high temperature alloys. He has contributed to 29 peer-reviewed journal articles including publications in Nature Communications and Nature Communications.