NASA's Internal Friction Reduction Tool Webinar

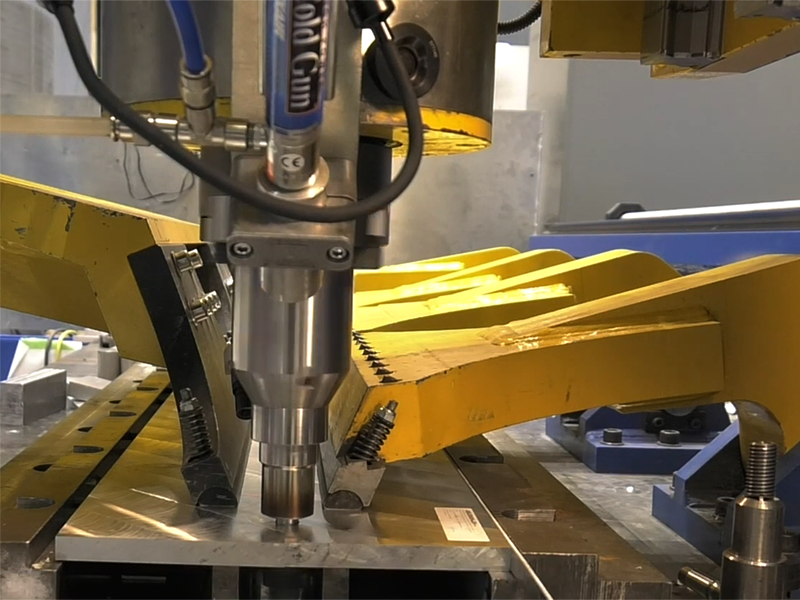

NASA's Marshall Space Flight Center has developed a cost-effective pin tool for use in self-reacting friction stir welding (SR-FSW), making the SR-FSW process significantly more robust and cost-effective. The IFR Tool mitigates the internal friction that occurs between the weld pin and crown-shoulder during a SR-FSW weld. Testing with the IFR tool has shown a significant reduction in the number of defects found in SR-FSW welds, and the tool allows significantly longer SR-FSW welds to be performed. Utilizing the IFR Tool can reduce SR-FSW welding costs by reducing scrap/rework rates, reducing the number of pin tools required per unit weld length, and reducing the time spent changing out SR-FSW pin tools per unit weld length. Along with improving the cost-effectiveness of existing SR-FSW applications, the IFR Tool may also further expand the applications for which SR-FSW is a commercially viable solution.

For more information on the technology, please click here.

During the webinar, you will learn about this new technology as well as how NASA’s technologies and capabilities are available to industry and other organizations through NASA’s Technology Transfer Program.